RootWave and Garford collaborate to develop eWeeding technology

The UK manufacturer of technologically advanced mechanical weed control products, Garford Farm Machinery, and Warwickshire based electrical weed control manufacturer RootWave, have today (11.06.2024) announced a new agreement that will bring next generation weeding technology to UK and international markets. The new agreement will see the two manufacturers co-develop new weeding technology and products, integrating electrical weeding into precision guided toolbar systems, for high-value and high-intensive crops as well as broadacre arable applications.

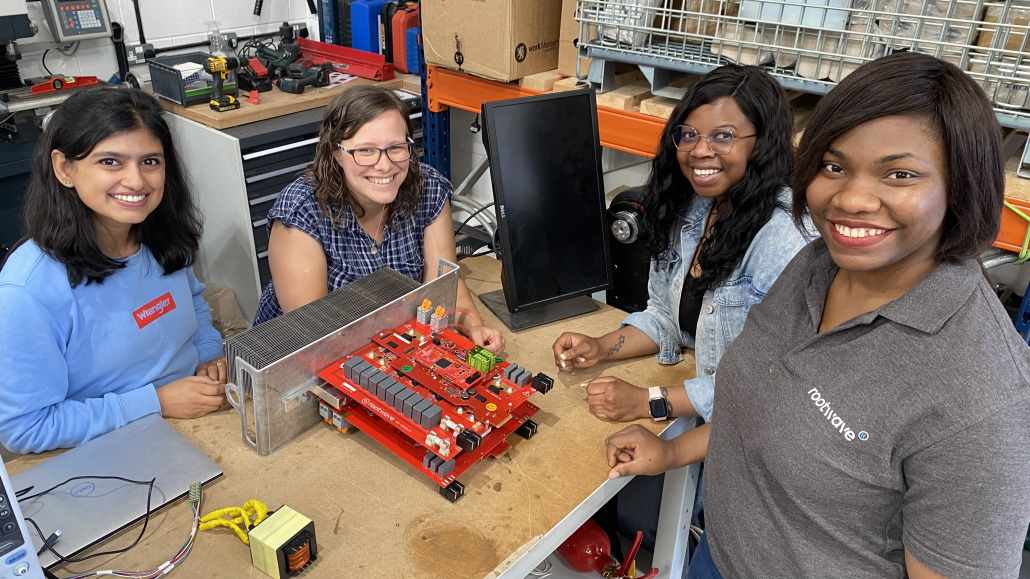

The RootWave system uses electricity to boil weeds and their roots. This makes electrical weeding highly effective and, because it is non-chemical and does not disturb the soil, it is compatible with both organic and regenerative farming systems. RootWave’s patented high-frequency alternating-current is orders of magnitude safer than direct-current, typically used in electrical weed control.

With over 20 years of hoeing experience, and having brought many innovations to market, from the Robocrop Vision Guidance System to the compact hydraulic side shift mechanism, Garford is recognised as the industry leader in precision mechanical weed control. The Robocrop Guidance System allows for accurate and efficient hoeing for both in row and inter-row weed management and prevention control. The system uses video cameras and image analysis computers to locate crop position and then guides the hoes quickly and accurately.

The new eWeeding technology is set to provide a cost-effective and high-performance solution, creating financial and environmental benefits, while supporting better quality crops that are not competing against weeds. Garford has calculated that by using the eWeeding technology, across a variety of different systems, estimated costs would come in between £55 to £120 per hectare, significantly lower than chemical herbicide costs.

RootWave CEO Andrew Diprose said, “Combining forces with Garford allows us to create a formidable solution for the industry, combining best-in-class power electronics, imaging and artificial intelligence to create an unrivalled weed control solution for vegetables, cereals and row-crops.

“It will alleviate the worries of farmers who are faced with an uncertain future where they don’t know if herbicides will be available, or will even be effective due to safety and resistance issues.”

Garford Managing Director Jonathan Henry said, “We are incredibly excited to pair Garford’s vast experience in precision guided hoes, with RootWave’s world leading expertise in power electronics.

“With the increasingly stringent controls over the use of chemical weed management, alongside resistance issues, we can support UK and global agriculture as it embraces its environmental responsibilities.

“Combining our technologically advanced precision guided weed control solutions, with the benefits of RootWave’s high frequency alternating current electrical weeding technology, we can create commercially viable and effective solutions to growers, as a key part of a sustainable, integrated weed management system.”